Have you ever considered how two seemingly different manufacturing domains (precision moulding and acrylic product design) are shaping today’s industries?

At first glance, mould parts and acrylic items may appear unrelated, yet they are united by the demand for customization, durability, and innovative design. Businesses across the world now seek customized mould parts for sale and customized acrylic products for sale to meet diverse industrial and consumer needs.

Understanding how these fields overlap reveals how innovation, efficiency, and personalization converge to define modern production.

The Significance of Customized Mould Parts

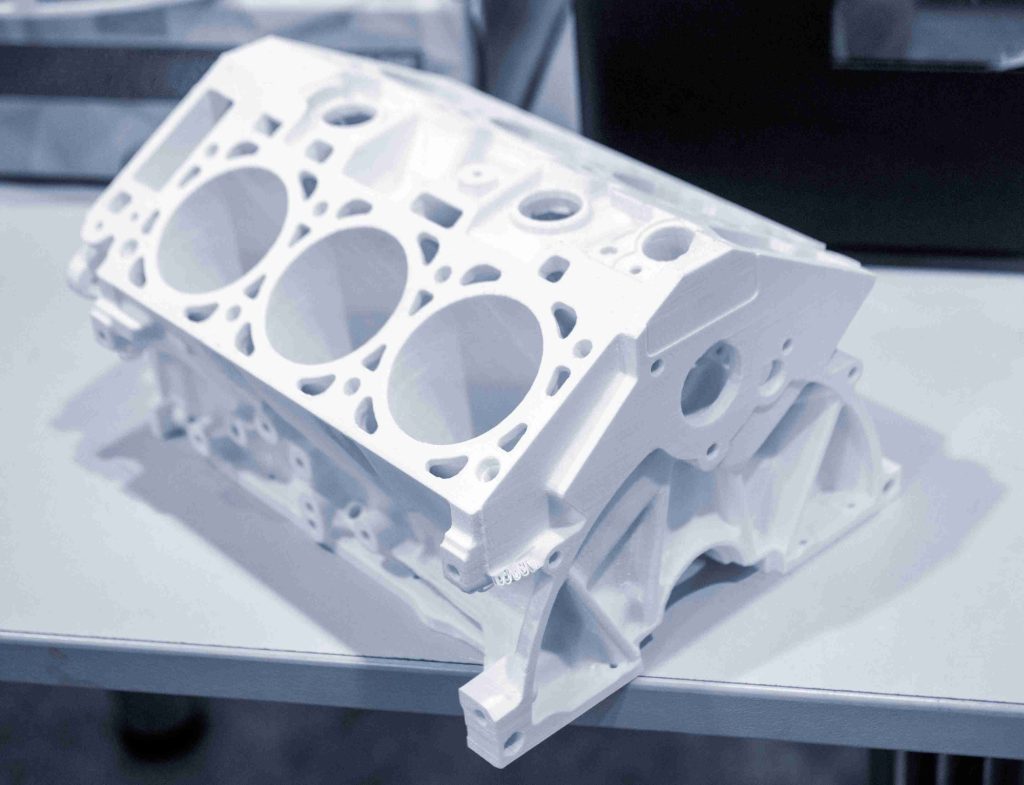

Customized mould parts are the backbone of countless industries, from automotive to healthcare. Unlike standard moulds, which are designed for broad applications, customized parts are tailored to exact dimensions and functional requirements. This precision allows manufacturers to reduce errors, increase efficiency, and produce components that meet tight tolerances.

For industries like automotive, where safety and performance are critical, having customized mould parts for sale ensures reliability. Companies in consumer electronics also benefit by using these parts to create slim, complex casings and intricate device components. In packaging, customized moulds streamline the production of bottles, caps, and containers that must balance strength with cost efficiency.

Advanced technologies such as CNC machining and electrical discharge machining (EDM) are transforming how mould parts are designed. By integrating 3D modeling and simulation tools, manufacturers can predict material behavior, test prototypes digitally, and reduce overall lead times. This makes customized mould solutions not only practical but also cost-effective.

Expanding Applications of Customized Acrylic Products

Acrylic products, once limited to simple sheets and displays, have evolved into versatile solutions across industries. The ability to mold, cut, polish, and engrave acrylic has expanded its applications into retail, hospitality, healthcare, and even aerospace. Businesses now actively search for customized acrylic products for sale because they combine durability, transparency, and design flexibility.

In retail, acrylic products dominate visual merchandising. Customized stands, signage, and shelves highlight products while maintaining a clean, modern look. In interior design, acrylic furniture and partitions add elegance without sacrificing strength. Healthcare facilities rely on customized acrylic solutions for durable barriers, protective equipment, and diagnostic device components.

Acrylic’s adaptability extends further through techniques like digital printing and laser engraving. Logos, colors, and unique textures can be embedded directly into acrylic surfaces, making every product distinctive. For businesses seeking brand identity or unique product presentation, customized acrylic solutions are unmatched.

The Intersection of Customization in Both Domains

While mould parts and acrylic products operate in different categories, they share a unifying principle which is “Customization”. Both industries thrive on precision and adaptability. Customized mould parts enhance production by ensuring exact component specifications, while customized acrylic products meet consumer demands for visual appeal and uniqueness.

In many cases, these two domains overlap. For example, the packaging industry relies on mould parts to produce containers, while acrylic is used for premium product displays. The furniture industry uses moulded components for structure while acrylic adds design features.

Together, they illustrate how modern industries blend technical accuracy with aesthetic design.

Market Insights: Growth and Regional Trends

The demand for customization is not a passing trend but a driving force in global markets.

The global plastic mould market was valued at approximately USD 12.5 billion in 2024 and is projected to reach USD 21.05 billion by 2032, growing at a CAGR of 6.2%. Meanwhile, the broader industrial mould market (metal, plastic, rubber, and hybrid) is forecast to rise from USD 29,200 million in 2024 to around USD 61,400 million by 2031, expanding at a CAGR of 11.2%.

On the acrylic side, demand is equally strong. The global acrylic products market is projected to approach USD 34 billion by 2035, growing steadily at a CAGR of 6.1%. Within this category, the cast acrylic sheet segment alone is expected to increase from USD 3.82 billion in 2025 to nearly USD 5 billion by 2030.

Regionally, Asia Pacific leads the market for both customized mould parts for sale and customized acrylic products for sale, driven by strong manufacturing hubs in China, India, and Southeast Asia. Mass production capacity, combined with advances in automation and CNC technologies, positions Asia as a global leader. In Europe and North America, the emphasis is on high-quality, smaller-batch customization with advanced finishes, particularly in healthcare, aerospace, and consumer goods.

Technological Advancements Driving Innovation

One of the most compelling aspects of both mould and acrylic production is how technology is redefining their potential. In mould manufacturing, predictive software, simulation models, and AI-driven process optimization ensure minimal defects and maximum efficiency. Additive manufacturing techniques, such as 3D printing, are being combined with traditional moulding processes to speed up prototyping and reduce development cycles.

For acrylic products, digital printing technology allows unparalleled customization. Businesses can now offer personalized acrylic signage, decorative panels, and functional products embedded with unique designs. AI-assisted cutting and polishing systems further enhance quality and consistency. This combination of artificial intelligence and digital printing underscores how advanced manufacturing is shaping the future of customization.

Future Opportunities for Customized Mould Parts and Acrylic Products

Looking ahead, the synergy between moulding and acrylic solutions presents exciting opportunities. Manufacturers offering customized mould parts for sale can expand their services to include value-added acrylic solutions, creating comprehensive product ecosystems. Similarly, suppliers of customized acrylic products for sale can leverage mould technologies to diversify their offerings into structural and packaging solutions.

Sustainability will remain at the core of future opportunities. Companies that adopt circular economy practices (recycling mould scrap materials or producing acrylic products with reduced carbon footprints) will find themselves ahead of regulatory pressures and consumer expectations. Emerging technologies like AI, IoT-enabled mould systems, and advanced digital fabrication techniques will further accelerate innovation.

Conclusion:

The convergence of precision engineering and design flexibility defines the current era of manufacturing. Customized mould parts for sale ensure accuracy and efficiency in production, while customized acrylic products for sale meet the growing demand for creativity and personalization.

Together, they illustrate how modern industries balance technical excellence with aesthetic innovation. Businesses that embrace these solutions are not only meeting present-day demands but also shaping a more efficient, sustainable, and customized future.